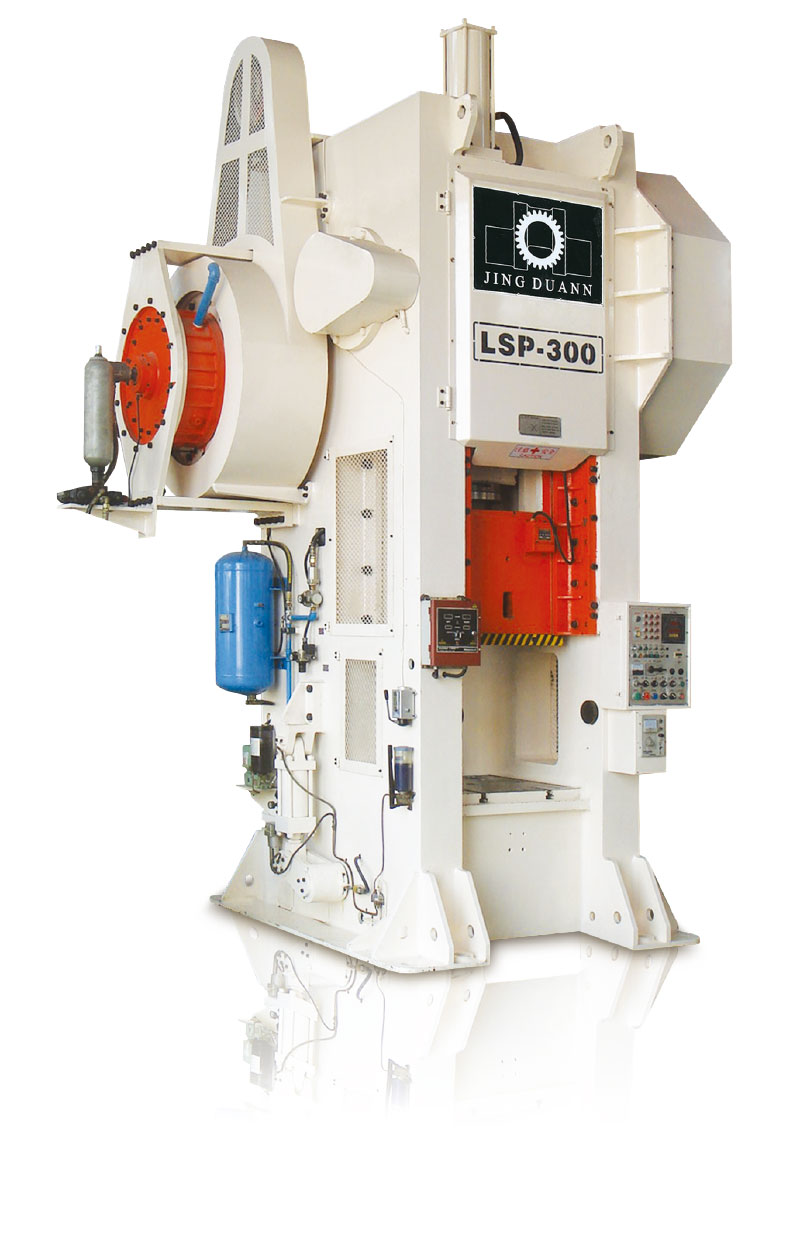

LSP High Speed Forging Presses 300-600

-

High Speed Forging Press FP-2500G Series suitable for manufacturing the forging involved in hand tools, autos, motorcycles, bicycles, trains, ships, airplanes, machine tools, textile machines, woodwork machines,conveying equipment, mining machinery, hardware parts'etc.

- Feature

-

1. The Box-type machine frame features rigid structure and reinforced by cross and longitudinal welding of steel plates. Improved machine rigidity can minimize the frame elongation during forging operation.

2. Side windows at both sides of the machine frame can equipwith automation transfer system to realize automatic forging, better production efficiency and less labor requirement.

3. The X-type slide guide ways design conquers the heat expansion of the slide during forging operation. It can absorb the slide clearance variation due to heat expansion, improve the slide

dynamic accuracy and better the forging precision.

4. High Forging Accuracy and less machining requirement. Suitable for Hot or Warm forging Operation.

5. Upward & Downward ejectors design can reduce the draft of mold cavity to minimize and save material consumption.

6. Motorized die height adjustment improves the thickness accuracy control while forging.

7. High stroke speed can reduce the contact time between molds and material while forge. Less contact time can extend the durability of molds.

8. The FP-2500G features with longer stroke which is different from the conventional short stroke press such that the machine is more suitable for conducting various kinds of forging operations.

9. Specially designed transmission system reduces noise.

10. Specially designed mold stick release mechanism helps the molds return in a fast speed and ensures easy operations.

11. Wider connecting rod design increases the allowance of eccentric load, enables multi-forging operations and ensures high-precision forging.

12. The centralized automatic lubrication system reduces frictions among various mechanical parts.

13. Circulated water cooling brake system with temperature detection.

14. Multiple safe circuit control design to protect the security of operators.

15. Our machines meets with the CNS inspection standards in terms of accuracy.

Specification

| Item / Model | Unit | LSP-300 | LSP-600 |

| Capacity | Tons | 300 | 600 |

|---|---|---|---|

| Stroke of ram | mm | 350 | 450 |

| Adjustment of ram | mm | 50 | 70 |

| Number of stroke | Spm | 20-35 | 25-35 |

| Work number of stroke | Spm | 15 | 15 |

| Shut height | mm | 800 | 930 |

| Rated tonnage point | mm | 15 | 20 |

| (L-R & F-B) Ram dimension | mm | 690*690 | 880*880 |

| (L-R & F-B) Table dimension | mm | 790*860 | 1000*1000 |

| (L-R & F-B) Side window | mm | 400*600 | 550*650 |

| Main motor | KWxp | 37kw*4p | VF55kw*4p |

| Ejector in the ram | Tons-mm | 3Ton-30mm | 3Ton-30mm |

| Ejector in the table | 噸-公釐 | 15Ton-100mm | 15Ton-80mm |

| Press weight | KG | 35,000 | 52,000 |

| (L*W*H*) Press dimension | mm | 2860*2954*4878 | 3280*3305*6170 |

Related Products