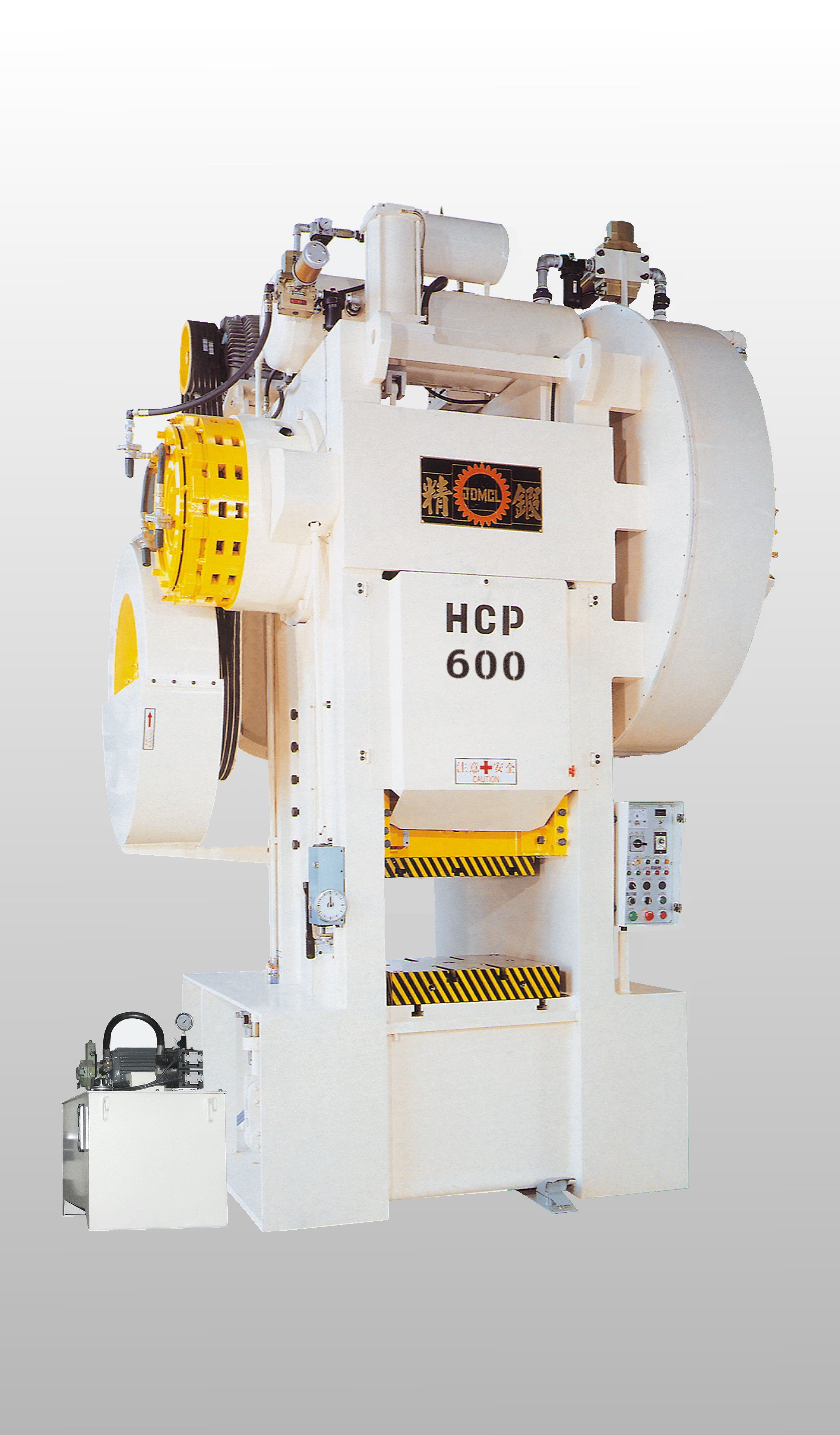

HCP Hot Forging Presses

-

High Speed Forging Press HCP Series is suitable for processing forging needed in hand tools, autos, motorcycles bicycles, trains, ships, machine tools, textile machines, woodwork machines, conveying equipment, mining machinery, hardware parts, etc. it's an indispensable machinery equipment for modernized forging plants, because it can produce precision forgings that can meet customer's quality and delivery requirements. The machine is a sharp production tool for forging plants.

- Feature

-

1. The machine is welded by high rigid steel plates, and being normalized for stress relieving, eliminated all the internal stress. It's well organized, has strong body, ensure heavy stroke and is permanently durable.

2. Use automatic centralized lubricate system, it is PLC controlled which is very reliable and can increase the life span of the machine.

3. Multiple safe circuit loop control, protect the machine and extend the life span of the machine.

4. The crank shaft is forged by S45C carbon steel. it's normalized after forging then machined and fine ground. It has super wearing-resistance and won't change shape ever.

5. The cycle time of one stroke is quite short that can eliminate the wearing of the molds and promote the production.

6. Precision fitted with CNS specification.

Specification

| Advantages | Design |

| High Production Efficiency Mold Life Cycle is Longer |

High Speed Stroke Ram and Bed Ejector Design. |

| High Precision Forging Parts Stable Product Quality | Extended Eight-Faced Guide Ways Unique Connecting Rod Design |

| Accurate Machine Structure Firm and Durable | Rigid Structure, Strong Shaft |

| Special Designed Devices Fulfill the Environmental Protection Standards |

Big Muffler to Reduce Noise Lubricant Recycle System Equipped |

| Operation High Safety Easy to operate | PLC Multi Circuit Loop System, Automatic Enforced Lube System |

| Iron, Aluminum, Copper and Titanium Alloys are Practicable in forging |

Ram Adjustment is 50mm High Torque |

| Item / Model | Unit | HCP-200 | HCP-300 | HCP-400 | HCP-500 | HCP-600 |

| Capacity | Tons | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| Stroke of ram | mm | 150 | 50 | 50 | 50 | 50 |

| Adjustment of ram | mm | 50 | 50 | 50 | 50 | 50 |

| Number of stroke | Spm | 100 | 80 | 90 | 85 | 100 |

| Work number of stroke | Spm | 18 | 16 | 18 | 16 | 16 |

| Shut height | mm | 450 | 600 | 480 | 510 | 600 |

| Rated tonnage point | mm | 5 | 5 | 5 | 5 | 5 |

| (L-R & F-B) Ram dimension | mm | 600*450 | 630*470 | 650*500 | 670*600 | 670*600 |

| (L-R & F-B) Table dimension | mm | 700*800 | 700*860 | 750*920 | 770*1100 | 770*1100 |

| (L-R & F-B) Side window | mm | 320*320 | 320*520 | 320*320 | 400*370 | 400*510 |

| Main motor | Kwxp | 18.5kw*6p | 30kw*6p | 37kw*6p | 37kw*6p | 45kw*6p |

| Ram of adjustment motor | Kwxp | 0.375kw*4p | 0.375kw*4p | 0.75kw*4p | 0.75kw*4p | 0.75kw*4p |

| Motor of lubrication | Kwxp | 0.1kw*4p | 0.1kw*4p | 0.1kw*4p | 0.1kw*4p | 0.1kw*4p |

| Ejector in the ram | Tons-mm | 3Ton-20mm | 3Ton-20mm | 3Ton-20mm | 3Ton-20mm | 3Ton-20mm |

| Ejector in the table | Tons-mm | 5Ton-40mm | 5Ton-40mm | 5Ton-40mm | 5Ton-40mm | 5Ton-40mm |

| Ejector hydraulic oil motor | Kwxp | 3.7kw*6p | 3.7kw*6p | 3.7kw*6p | 3.7kw*6p | 3.7kw*6p |

| Air pressure | kg/cm2 | 5 | 5 | 5 | 5 | 5 |

| Press weight | kg | 17,500 | 22,000 | 27,000 | 32,000 | 35,000 |

| (L*W*H*) Press dimension | mm | 2550*2135*3820 | 2630*2181*4245 | 2675*2307*4068 | 2829*2490*4310 | 2829*2490*4450 |

Standard Accessories:

| Overrun Protection System | Automatic Lubrication System | Ejector Control System |

| Angle Indicator | Working light | Mold Height Indicator |

| Motor drive/ Manual Mold height Adjustor |

Related Products